We understand that for many converters the purchase of a pull test machine represents a significant investment. Therefore, as a service to our customers, we offer in-house pull testing.

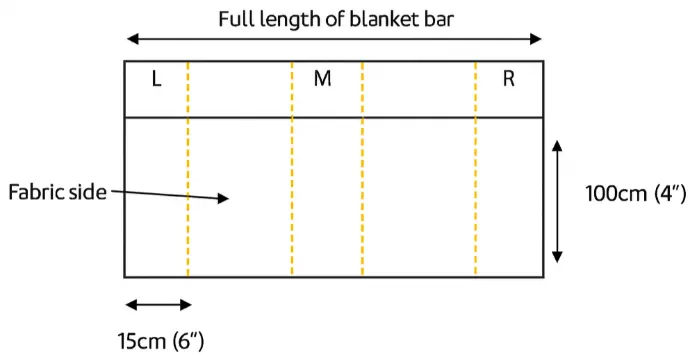

For the best possible results, please convert the sample using the full bar length (the across dimension) and 4" on the around dimension.

If you want faster service, please cut your sample blanket into three separate 15c, (6") wide test strips. Looking down at the fabric side, label them as seen above: Left (L), Middle (M), and Right (R).

Please include the following information on each test strip:

- Bar Name

- Blanket Name

- Blanket Gauge

- Glued (y/n)

- Glue type

- Mounted thickness as measured by your team

Our testing procedure:

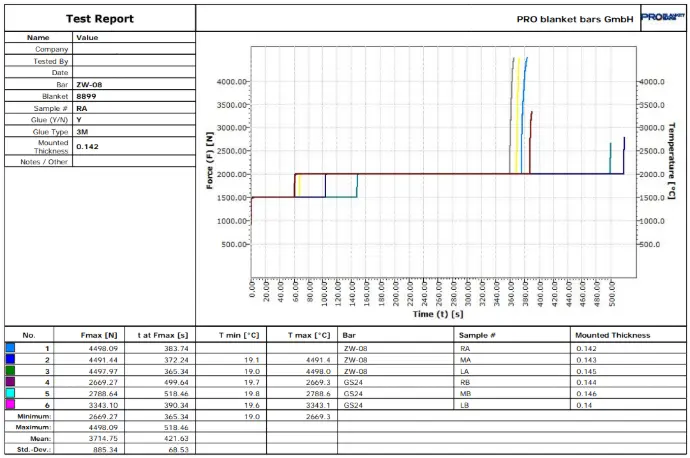

- These test strips are mounted in our machine, where we slowly increase pressure to 2000N

- After 5 minutes at 2000N, our machine continues to incrementally increase pressure until either a bar pull or blanket destruction.

The analysis

After testing, we will email you the test results along with a brief description of what we observed as well as recommendations for improvement. If requested, we will also return the finished test pieces for your own records.

Explanation of Results

Most blanket bar failures result from one of the following:

- Insufficient mounted thickness or high spot on blanket

- Solution: Check press brake and ensure even pressure and closure all the way across

- Solution: Shim one or more sides of the brake to achieve an even mounted thickness

- Glue problems

- Solution: Ensure even application across blanket

- Solution: Check mix ratio – most epoxies require a 1:1 by weight mixture

- Solution: Make sure glue is not partially cured before application (this can happen inside nozzles that have been abandoned during lunch, etc.)

Disclaimer

Because of the wide variety of manufacturers, presses, lock-up mechanisms, epoxies, and converting conditions, we cannot possibly replicate or measure every potential situation during conversion or while on press. The results of our assessment do not constitute any guarantee that these results will be consistently achieved in the future, nor that they are sufficient for any and all press applications. It is up to the converter to ensure that they are following their own internal best practices for obtaining superior bar adhesion.